HOWA-TECH BEARINGS

Customized Engineered Slide Bearings

A diverse in-dept experience base coupled with a wide range of Sliding Bearing materials enable our expertise integration into Offshore, Hydropower, Renewable Energy, Hydraulic Steel Construction, Metallurgy, Mining, Port, Lifting & Material Handling and Machine Construction industries.

HOWA-TECH BEARINGS

applications

Howa’s engineering team possesses extensive product and application knowledge. These benefits our customers from the first idea-sketch, specific design calculation to final installation support and project documentation. We aspire to set new standards in developing bearing solutions for applications with extreme requirements. Be it a tough working environment, an extra-long lifespan demand or ultra-high loads, we engineer the solutions to your specific applications.

Offshore - Fairleads

Anchoring an FSO/FPSO or a Semisubmersible Oilrig to the seabed, means trying to predict the mood of mother nature. The Bearings in mooring mechanisms such as chain stoppers or fairleads are exposed to exceptional high and rapidly changing forces, sea-water submersion or splash and must fulfil life-span guarantees of typically 20-30 years and beyond.

We won’t get nervous by these requirements, as we have the right bearing materials on hand and proof their suitability.

Other Applications:

F(P)SO: Riser Winch, Sheave Systems, Fairleads, Chain-Stoppers

Semi-Sub Oilrig: Fairleads, Winches, Cranes, Heave-Compensation

Jackup Rig: Leg Guides, Cantilever Guides, Jacking System

Hydromechanical - Radial Gate

Who can see decades into the future? We can!

They are indispensable; either they protect hundred thousand of households from flooding or they manage billions of cubic metres of water to generate green energy. A radial gate must never fail when in need to operate, the impact could lead to catastrophic outcomes.

Therefore, the bearing in such structures is a key component to guarantee flawless articulation of the gate. There are only less than a hand-full of bearing materials which can cope with the demanding requirements:

- high dynamic forces

- very slow rotational speed

- potentially wet environment

- long non-operational periods

- potentially no external lubrication

- and the long life-time requirements of commonly up to 50 years

Since these gates can get massively large, we are ready to produce them virtually to any size. Your requirement is to go beyond 1 metre of pivot shaft diameter? No problem for us and we’ll make sure they will meet your lifetime requirements.

Other Applications: Shiplifts, Mitre Gates, Flapgates, Fish Passing Facilities, Guide Rollers

Mining, Material Handling and Processing

Regardless if it’s in the mine or in the processing plant, 24/7 operations are the industry standard.

Overhauls and part replacements (incl. bearings) are only possible during a scheduled maintenance. Unexpected bearing failures would lead to time -and money loss.

Therefore, only strong, tough and hard-wearing bearing materials are used for this rough working environment. The rotation hinges on this massive steel construction are commonly furnished with standard maintenance-free Spherical Plain Bearings. The thin sliding layer on these bearings is often detached prior to reaching an adequate life-span. When that happens, the bearings generate severe noises and heavy wear on the bearing sliding surfaces. A bearing replacement is inevitable.

Our proven bearing solutions guarantee a flawless bearing performance even without grease lubrication. But in case greasing of bearing is desired, our materials allow for it.

Metallurgy - Ladle

They are dark, loud, dusty and yet utterly stunning.

Steel making equipment puts high demands on bearing materials. Unexpectedly the biggest of them all is not the high temperature, but the dust generated by the steel making process and the handling of raw materials.

The fine dust particles enter any small gap between bearing & shaft and accelerate bearing wear. The key is to implement a bearing material which is able to handle foreign particles but also to perform in the absence of grease – as many applications are still too hot for an adequate lubrication performance of grease.

Other Applications: Ladle Arms, Shears, Scrap Buckets, Arc Furnace Columns, Transport Rollers, etc

Pipelay – Stinger

These large steel structures are probably the most visually striking attachment a ship can ever get. Often more than 100 metres in length and hundreds of tones heavy, these stingers guide welded pipes via guide-rollers smoothly into the water. A single pair of hitches, with bearings in it, form the main-hinge connection between stinger and ship.

Permanent sea-water splash, misalignments and multidirectional high forces put a special set of requirements to the bearing material. We have the answer to this challenge and offer the bearings in various design approaches.

Other Applications: Roller Boxes, Pipe Handlers, Tensioner, etc

Marine - Ship Ramps

Cars, trucks and other heavy vehicles roll over it by the hundreds, each time when it stretches out to connect the ship with the land – the quarter ramp. Probably one of the larges moving elements on a cargo ship, these ramps can weigh several hundred tones.

The rotation hinges on this massive steel construction are commonly furnished with standard maintenance-free Spherical Plain Bearings. The thin sliding layer on these bearings is often detached prior to reaching an adequate life-span. When that happens, the bearings generate severe noises and heavy wear on the bearing sliding surfaces. A bearing replacement is inevitable.

Our proven bearing solutions guarantees a flawless bearing performance even without grease lubrication. But in case greasing of bearing is desired, our materials allow for it.

On other type of ramps, it can’t be avoided some Bearing hinge points may be submersed in water or located in splash-zones. That is also easily addressed with our corrosion-resistant and maintenance-free bearing materials.

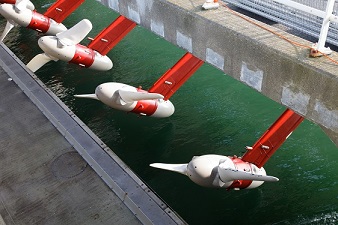

Renewable

The future is bright!

The industry of renewable energy has increased its pace and new developments are conquering the land and the seas.

An emerging sector is the Tidal Energy, applying submersed and anchored turbines.

The anchoring and turbine actuation mechanisms is relying on pivotal hinges with bearings. Needless to say, that permanent contact with sea-water is the biggest challenge for the bearings. Our vast experience in the offshore and subsea sector enabled us to have the right bearing solutions ready to be implemented.

Port Handling - Quay Crane

With the first glance they remind on a Brachiosaurs – just that these cranes are even mightier.

Lifting safely hundreds of containers per day from ship to shore, these cranes have a busy schedule to fulfil. With each new ship arriving, the ultra-long crane boom will be lowered into the horizontal and prior to dispatch, the boom is lifted in an almost vertical position.

The main hinge of this boom is usually equipped with conventional bronze bearings, making this part of the crane a high- maintenance setting. Automated grease-lines may fail unexpectedly, causing the bronze bearing to run dry and wearing it in a highly accelerated manner.

We cater for a number of self-lubricating and high-strength bearing materials which are a proven solution for a long-term failure-free operation.

Other Applications: Forestay, Bogie Systems, RTG’s, Spreaders, etc.

Construction and Material Handling

This industry is widely spread with endless types of equipment and applications. Sometimes the simplest and cheapest bearing material is the perfect choice and in other equipment, it can only be the toughest bearing material. We cater for them all with our conscious pragmatic approach on the bearing selection

Typical Applications: Tower Cranes, Piling Equipment, Concrete Pumps, Boom Lifts, Excavators, Crawler Cranes, etc.

Dredging

There are several techniques of dredging but what they all have in common is that they have numerous custom-designed equipment on deck which pivots, skids or aligns. Not only that calls for special bearing designs but also the harsh working environment narrows down the selection of the right bearing material.

Seizure, premature wear and corrosion, these are the typical symptoms of bearings working in dredging equipment’s.

A vast number of bearings will be operating under water or in splash-zones, which makes grease-lubrication ineffective but also allowing dispersed dredge particles to enter the bearing, leading directly to premature wear for most common bearing materials.

A thoughtful selection of bearing material, paired with an unconventional design approach and a deliberate specification of all mating components will lead to a long-lasting bearing solution.

Other Applications: Drag-and Cutter Head, Cutter Ladder, Anchor Boom, Spud Carrier, Excavator, Sheaves, A-Frames, etc.

Buildings and (movable)

Structures

No matter how heavy and ridged they appear to be – they will and must move; large bridges, facades, roofs and other special structures. Expansion and contraction from temperature changes, the power of wind and water are impactful elements to the structure and can best be addressed by the implementation of bearings.

Micromovements, ultra-slow sliding speeds, permanent force, decades of life-span needs, exposure to dust and water are often the minimum of requirements raised to a bearing for these high-profile applications.

It’s a long list, but just nice to make full use of our bearing material’s capabilities.

Other Applications: Bridge Bearings, Expansion and Contraction Joints, Movement and Settlement Joints

Agriculture

The bearing tasks for this mass-produced equipment are straight forward: Cost-effective, simple, robust and durable.

For special applications we gladly work on a custom-design, otherwise proven mass-produced bearing materials are available to serve you well.