HOWA-TECH BEARINGS

products

Our material range combines nearly all high-performing Sliding Materials. For easy selection, we categorised them in four main groups.

HOWA SOLID MACHINED BEARINGS

Developed to meet the toughest and most unique application requirements.

Most materials of this category combine following features:

- Exceptional durability

- Self-lubricating

- Wide range of temperature resistance

- Low wear rates

- Operation in Sea-water or chemicals

- Handling of shock loads and misalignments

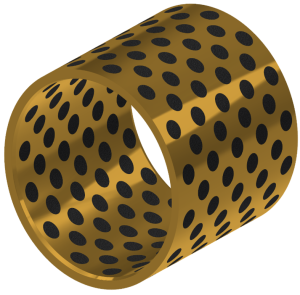

HOWA SLB

Bronze Alloy with Incorporated Solid Lubricant Plugs

Material Grade

120

150

280

480

Max. Load Capacity Dynamic

N/mm2

60

95

170

180

Max. Load Capacity Static

N/mm2

130

180

280

330

Coefficient of Friction

dry

0.08-0.12

0.10-0.12

0.10-0.15

0.12-0.17

Coefficient of Friction

greased

0.06-0.10

0.06-0.20

0.08-0.12

0.08-0.12

Max. Sliding Speed

m/s

0.6

0.4

0.4

0.2

PV Value

N/mm2*m/s

1

1

1.5

1.2

Temperature Strain

min. / max.°C

-40/250

-40/300

-40/350

-40/350

HOWA BRZ

Bronze Material in Various Alloys

Material Grade

90

120

150

280

480

Load Capacity Dynamic (Dependent on Grease Pressure Resistance)

N/mm2

50

60

70

120

120

Max. Load Capacity Static

N/mm2

130

160

220

340

400

Coefficient of Friction

greased

0.06-0.10

0.06-0.10

0.06-0.20

0.08-0.12

0.08-0.12

Max. Sliding Speed (Grease Lubricated)

m/s

3

2.5

2

2

1

Temperature Strain

min./max.°C

-40/250

-40/250

-40/300

-40/350

-40/350

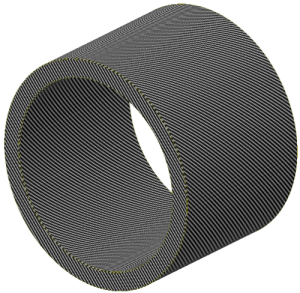

HOWA COMP

Fibre Reinforced Polymer Composite

Material Grade

785

786

787

788

Compressive Strength

N/mm2

345

345

310

350

Max. Load Capacity Dynamic

N/mm2

80

80

60

80

Max. Load Capacity Static

N/mm2

200

200

180

200

Coefficient of Friction

dry

0.13-0.18

0.10-0.12

0.07-0.09

0.13-0.18

Coefficient of Friction

greased

(<0.1)

(<0.1)

(<0.1)

(<0.1)

Max. Sliding Speed (Grease Lubricated)

m/s

0.1

0.1

0.2

0.1

PV Value

N/mm2*m/s

0.75

1

1.25

0.5

Temperature Strain

min. / max.°C

-70/100

-70/100

-70/100

-70/150

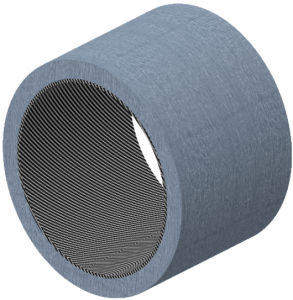

HOWA COMP FG

PTFE Lining with Fibreglass Backing

Compressive Strength

N/mm2

350

Max. Load Capacity Dynamic

N/mm2

140

Max. Load Capacity Static

N/mm2

210

Coefficient of Friction

dry

0.04-0.1

Max. Sliding Speed (Grease Lubricated)

m/s

0.1

PV Value

N/mm2*m/s

1.5

Temperature Strain

min. / max.°C

-70/140

HOWA STL

Hardened Bearing Steel

Max. Load Capacity Dynamic (Depandant on Grease Pressure Resistance)

N/mm2

150

Max. Load Capacity Static

N/mm2

400

Coefficient of Friction

greased

0.15-0.3

Max. Sliding Speed (Grease Lubricated)

m/s

0.2

PV Value

N/mm2*m/s

1.5

Temperature Strain

min. / max.°C

-30/300

HOWA STL-MN

Hardened Manganese Steel

Max. Load Capacity Dynamic

N/mm2

70

Max. Load Capacity Static

N/mm2

500

Coefficient of Friction

dry

0.15-0.25

Max. Sliding Speed (dry)

m/s

0.1

PV Value

N/mm2*m/s

0.5

Temperature Strain

min. / max.°C

-50 / 400

HOWA FAB-X

PTFE Fabric Liner on Various Material Backings

Backing Material

Bronze

Mild Steel

Stainless Steel

Load Capacity Dynamic

N/mm2

180

180

200

Load Capacity Static

N/mm2

250

280

300

Coefficient of Friction

dry

0.03-0.06

0.03-0.06

0.03-0.06

Max. Sliding Speed

m/s

0.15

0.15

0.15

Temperature Strain

min./max.°C

-50/150

-50/150

-50/150

HOWA SINT

Oil Impregnated

Sintered Bronze

Max. Load Capacity Dynamic

N/mm2

10

Max. Load Capacity Static

N/mm2

50

Coefficient of Friction

dry

0.05-0.15

Max. Sliding Speed (dry)

m/s

6

PV Value

N/mm2*m/s

1.7

Temperature Strain

min. / max.°C

-20 / 120

HOWA SMG

Homogenous Bearing

Alloys made with

Powder Metallurgy

Material Grade

SMG 520

SMG 523

SMG 524

SMG 530

SMG 533

SMG 535

Compressive Strength

N/mm2

250

350

400

560

400

380

Max. Load Capacity Dynamic

N/mm2

90

115

130

70

50

55

Max. Load Capacity Static

N/mm2

180

230

250

155

100

105

Hardness

HB

55

85

50

80

45

40

Coefficient of Friction

dry

0.11-0.16

0.12-0.18

0.14-0.21

0.25-0.45

0.25-0.45

0.30-0.50

Coefficient of Friction

in water

0.10-0.14

0.11-0.17

0.13-0.18

–

–

–

Max. Sliding Speed

m/s

0.35

0.35

0.5

0.2

0.2

0.2

PV Value

N/mm2*m/s

1.5

1.5

1.5

1.0

0.8

0.8

Temperature Strain

min. / max.°C

-100/350

-100/350

-100/350

0/650

-200/200

-200/450

Min. Counter Material Hardness

HRC

35

45

20

45

45

45

Base Metal Alloy

Bronze

Bronze

Bronze

Iron-Nickel

Nickel

Nickel-Copper

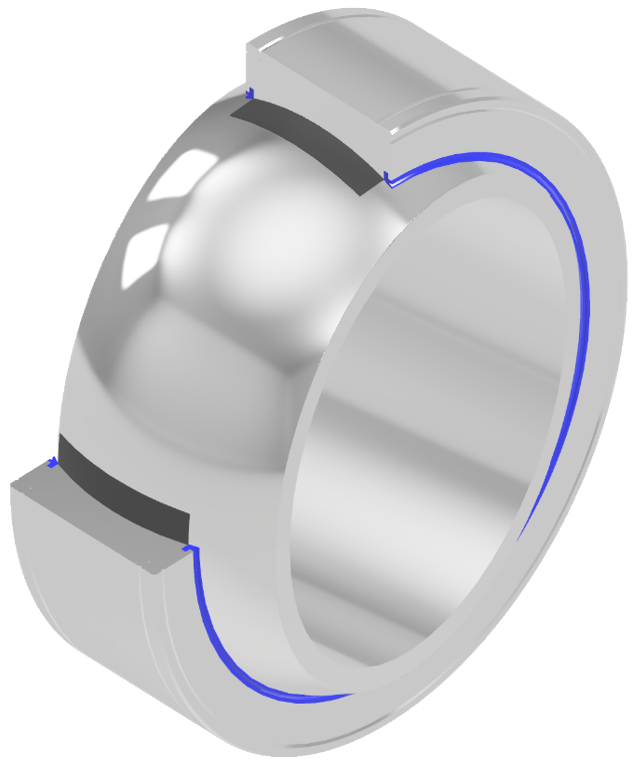

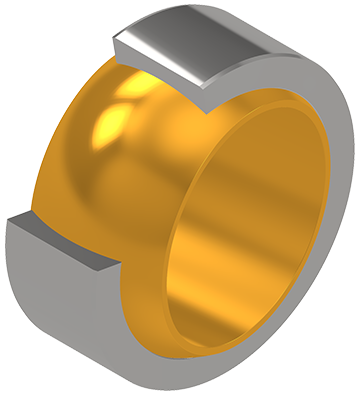

HOWA SPHERICAL PLAIN BEARINGS

These self-aligning bearings are offered as standard steel bearings and as ultra-versatile SLB and COMP types.

HOWA SPHERE SLB

HOWA SPHERE SLB Bearing Material Paired with Stainless Steel

- Highly Robust and Extremely Wear-Resistant

- Maintenance-Free but Lubrication Permitted

- Corrosion Resistant and Non-Seizing

- Sea-Water Resistant

- Available as Fixed and Floating Bearing

- Sized in Accordance to ISO 12240 but also Customisable

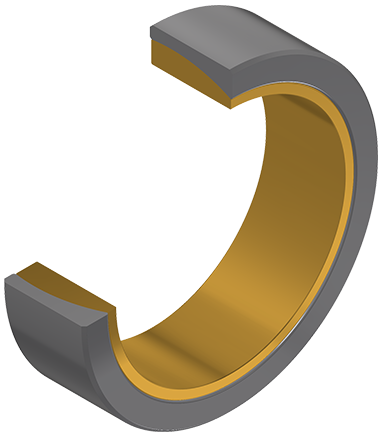

HOWA SPHERE COMP

HOWA SPHERE COMP Bearing Material Paired with Stainless Steel

- Wear Resistant and Low Friction Bearing

- Maintenance-Free but Lubrication Permitted

- Ideal for Micro-movements

- Corrosion Resistant and Non-Seizing

- Sea-Water Resistant

- Available as Fixed and Floating Bearing

- Sized in Accordance to ISO 12240 but also Customisable

HOWA SPHERE STL

HOWA SPHERE STL, Hardened Bearing Steel

- Available as Lubrication-Bound and Self-Lubricating Bearing

- Dimensions are in Accordance to ISO 12240

- Suitable for a Wide Range of Applications

- High Quality and Cost Effective

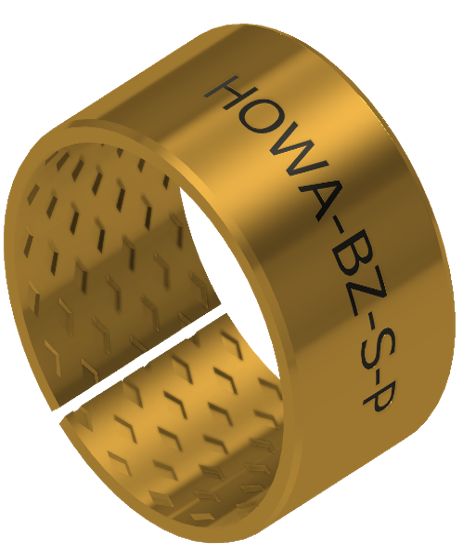

HOWA ROLLED BEARINGS

Proven in the market for decades especially in series production for the following reasons:

- Standardised to ISO 3547 (DIN1494)

- Suit demands of wide range of applications

- Slim and compact design

- Inexpensive and fast availability

- Durable and maintenance-free materials available

- Sufficient lifespan to meet most repair intervals

HOWA PF

PTFE Coated Bearing with Various Backing Materials

Max. Load Capacity Dynamic

N/mm2

140

Max. Load Capacity Static

N/mm2

250

Coefficient of Friction

dry

0.03-0.15

Max. Sliding Speed

m/s

2.5

PV Value

N/mm2*m/s

1.6

Temperature Strain

min./ max.°C

-200 / 250

HOWA PM

POM Resin Coated Steel Backing

Max. Load Capacity Dynamic

N/mm2

140

Max. Load Capacity Static

N/mm2

250

Coefficient of Friction

greased

0.03-0.10

Max. Sliding Speed

m/s

2.5

PV Value

N/mm2*m/s

2.6

Temperature Strain

min./ max.°C

-40 / 170

HOWA BZ

Tin-Bronze with Lube Pockets

Max. Load Capacity Dynamic

N/mm2

60

Max. Load Capacity Static

N/mm2

150

Coefficient of Friction

greased

0.06-0.15

Max. Sliding Speed

m/s

2.5

PV Value

–

2.8

Temperature Strain

min. / max.°C

-40 / 200

HOWA BMG

Graphite Impregnated Bronze Layer on Various Backing Materials

Max. Load Capacity Dynamic

N/mm2

150

Max. Load Capacity Static

N/mm2

280

Coefficient of Friction

dry

0.13-0.22

Coefficient of Friction

greased

0.10-0.15

PV Value

–

0.4

Temperature Strain

min. / max.°C

-80 / 250

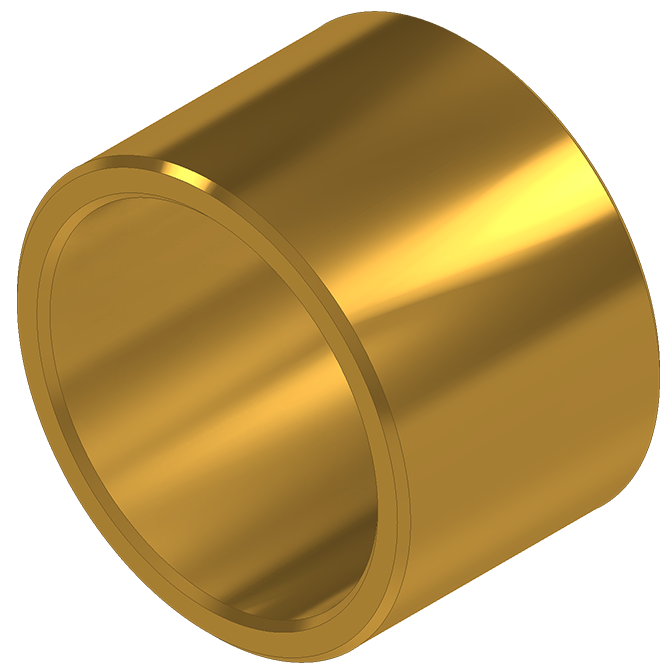

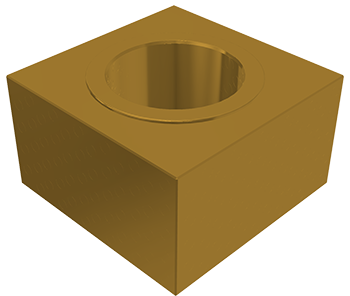

HOWA CUSTOM DESIGN BEARINGS

At HOWA it is our aim to design the most practical, cost-effective and application-based-performing bearings. We always approach each project with an open mind, considering the experience from similar applications and yet thinking from scratch again.

All bearings from the Solid Machined Bearings range are produced-to-order. That offers full flexibility to achieve special geometrical shapes, sizes, tolerances, design features and anything else which make our bearings the most suitable for your application.

Applying our vast design experience, we develop custom-bearings for the most demanding and unique application requirements. Reach out to our Howa Team and get expert support.

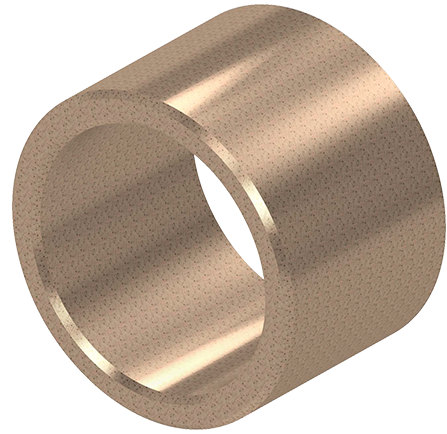

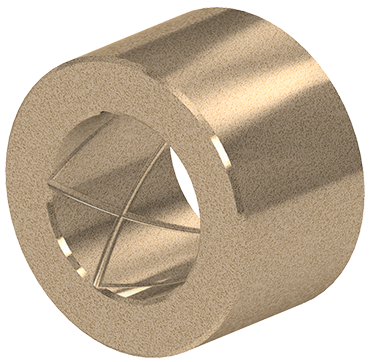

Straight Bearing

The simple shape of a straight bush is the most commonly used bearing geometry, allowing the transfer of radial forces. Lubrication grooves and holes, cut-outs, etc. can be included with full flexibility.

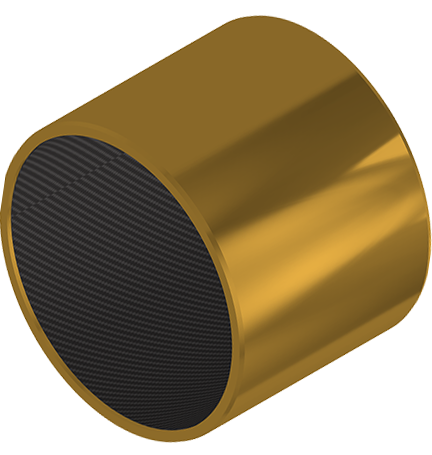

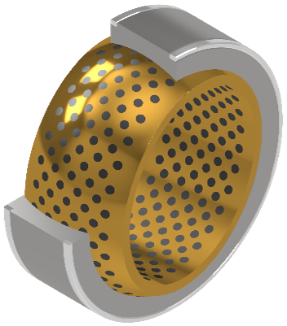

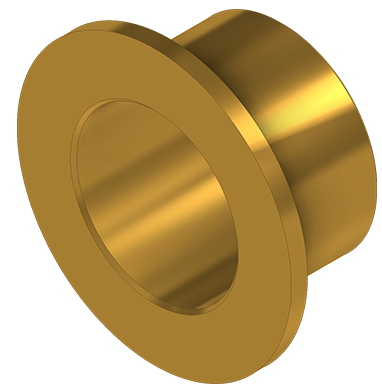

Flanged Bearing

Next to radial forces, this bush design transfers axial forces via the flange face. The bush can be machined with mounting holes, lubrication channels, special dimensional tolerances and many other features.

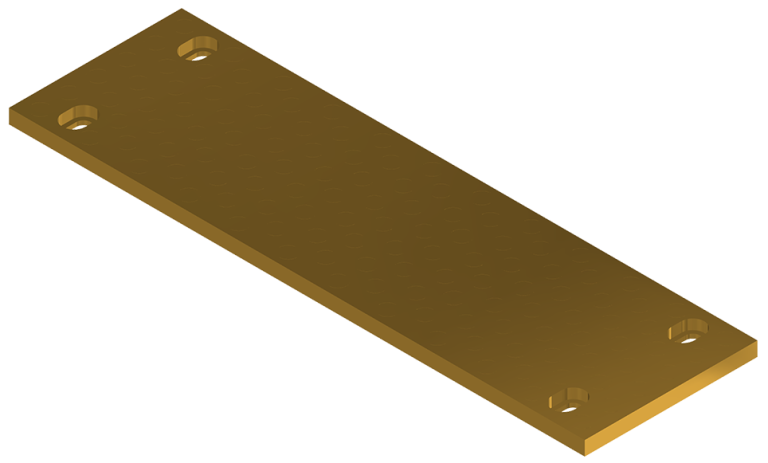

Liners / Plates

Liner plates allow sliding motion in X and Y direction. They are available in round, oval, rectangular and square shapes featured with lubrication grooves, recessions and mounting features such as countersunk and tapped holes.

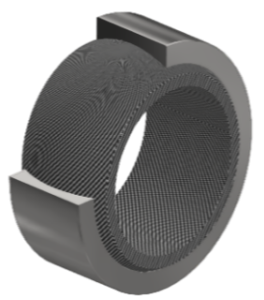

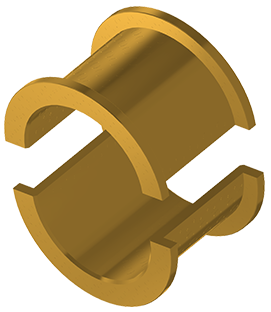

Half-Shell Bearings

A pair of Half-Shell Bushes is used when the assembly situation (or during future repairs) is unfavourable to the common axial assembly direction of the shaft. The shells are machined into perfect halves of each 180 degrees, ensuring full concentricity once installed into bore.

Spherical Plain Bearings

The matching spherical surfaces enable the bearing to self-align and balance-out misalignments of the adjacent structure. Our Spherical Plain Bearings follow the dimensions of DIN EN 12240-1 standard.

For all unique and highly demanding applications, we gladly go beyond this standard to create new design variations and develop the highest performing and the most cost-effective custom bearings.

Asymmetrical Spherical Plain Bearings

This design approach enables the spherical bearing to handle significantly higher axial forces than the standard radial bearing design. Its compact design minimises installation spaces and makes costly combinations of single Radial and Axial Bearings redundant.

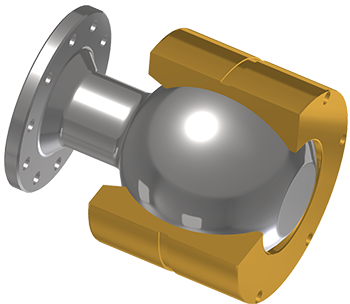

Spherical Trunnion Bearings

This compact bearing design is meant to handle bi-directional radial – and axial forces occur. It can handle large misalignments through a flexible tilt angle setting. This bearing eliminates the need for complex bearing combinations and convinces with uncomplicated installation requirements.

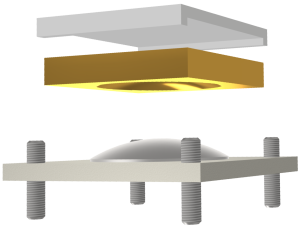

Spherical Plates

Ideal for implementation in large steel structures where parallelism and dimensional accuracy are uncertain. The spherical surface accommodates omni-directional rotation and ensures even load distribution. The flat surface on the opposite site enables linear sliding motion to compensate expansion and contraction.

Typical applications are bridges, large roof and pipe structures and other heat generating installations that need underlay thermal contractions and expansions.

Special Shaped Bearings

Virtually any mechanically machinable shape can be transformed with our vast material selection into a sliding bearing. Single or multiple sliding surfaces, various bearing directions and anything else which seems impossible at first sight, is our speciality.